OPTIX GLASS Z-XOTKtcdDb ITU-T G.652D 1.0kN (40m SPAN) 4km REEL

Starting at €616.80 €501.46

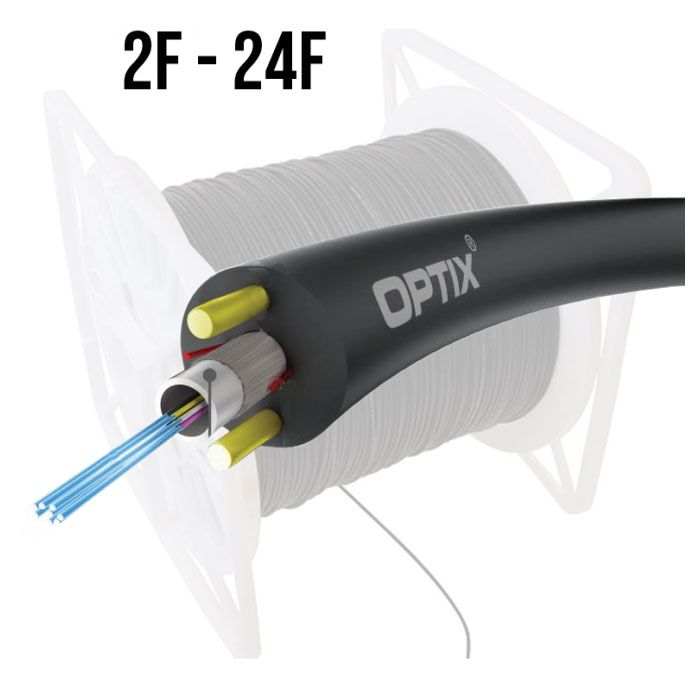

OPTIX Cable GLASS Z-XOTKtcdDb 1.0kN, 2-24J (up to 40m SPAN – NESC Heavy) 9/125 ITU-T G.652D RELL

OPTIX GLASS Z-XOTKtcdDb: A light single-tube construction (25-30kg/km), great flexibility and durability against dragging despite its small diameter (5.5mm for12J, 6.0mm for 24J). Water blocking gel and construction (WB), HDPE coating, UV radiation resistant, working temperature range: -20°C - 70°C, reinforced with 2 ARP (∅0.5mm) or FRP (∅0.4mm) rods, as well as glass yarns, fully dielectric - Z-XOTKtcdDb equivalent. Maximum installation tension: 1000N.

All cable fibres are colour coded according to the "EIA/TIA-598" standard. The tube has up to 24 fibreglass threads and is filled with a hydrophobic gel for protecting the threads against moisture and vibrations. The cable is reinforced with the help of glass yarns. For additional construction durability two ARP/FRP rods have been molten into the HDPE coating. Two ripcords have also been molten into the coating that make the removal of the outer layer easier. The cables are meant for installation in primary and secondary tele-technical canalisation by pneumatic (cable blowing) and mechanical (cable jetting) means, as well as for aerial installation on a span of up to 40m.

Features

- Universal cable for aerial/canalization installation

- Span (NESC Heavy) up to 40 meters (1kN)

- Fully dielectric construction

- Resistance to high and low temperatures

- Enhanced by high quality glass yarns

- Solid HDPE jacket

Cable contruction

- Optical fibres in 0.25mm coloured coating

- Loose tube

- Ripcords to tear the outer jacket

- ARP rods

- HDPE outer jacket (black), UV stabilized

- Glass yarns

| Product information | ||||||||||

| Cable version |

The total amount of fibres [pcs] |

Weight [kg/km] (±10%) |

∅ Cable [mm] (±0.4) |

∅ Tube [mm] (±0.15) |

Supporting element/ Peripheral reinforcement |

Reinforcing element [mm] (±0.1) |

Coating material & thickness [mm] (±0.2) |

Temp. range instalation |

Temp. range operating transport |

Minimum bending radius temporary permanent |

| 1T2F | 2 | 25 | 5.5 | 1.4/2.0) | Glass yarns | ARP(2x0.5) | HDPE(1.5) | -20° to +70°C | -20° to +70°C | 20D/10D |

| 1T4F | 4 | 25 | 5.5 | 1.4/2.0) | Glass yarns | ARP(2x0.5) | HDPE(1.5) | -20° to +70°C | -20° to +70°C | 20D/10D |

| 1T8F | 8 | 25 | 5.5 | 1.4/2.0) | Glass yarns | ARP(2x0.5) | HDPE(1.5) | -20° to +70°C | -20° to +70°C | 20D/10D |

| 1T12F | 2 | 25 | 5.5 | 1.4/2.0) | Glass yarns | ARP(2x0.5) | HDPE(1.5) | -20° to +70°C | -20° to +70°C | 20D/10D |

| 1T24F | 24 | 30 | 6.0 | 1.9/2.5) | Glass yarns | ARP(2x0.5) | HDPE(1.5) | -20° to +70°C | -20° to +70°C | 20D/10D |

| Mechanical parameters | EN standard | IEC standard | 1-8F | 12F | 24F |

| Tensile Strength Installation (NESC Heavy) | EN 187000 | IEC 60794-1-2-E1 | 1000N | 1000N | 1000N |

| Tensile Strength Operation (NESC Heavy) | EN 187000 | IEC 60794-1-2-E1 | 500N | 500N | 500N |

| Crushing resistance | EN 187000, m.504 | IEC 60794-1-2-E3 | 500N (100x100mm) for 60 sec. | ||

| Repeated bending | EN 187000, m.507 | IEC 60794-1-2-E6 | 30 cycles [(20xD), 1kg] | ||

Please complete your information below to login.

Sign In

Create New Account