OPTIX STRONG ZKS-XOTKtsFf ITU-T G.652D 2.0-3.0kN

Ab 1,07 € 0,87 €

OPTIX Cable STRONG ZKS-XOTKtsFf 2.0-3.0kN 9/125 ITU-T G.652D

DUCT CABLE

- Improved rodent protection

- Solid HDPE jacket

- Water blocking construction

- Designed for direct access in the ground

- Resistance to high and low temperatures

- Enhanced by corrugated steel tape

- Practical and thin Ripcord

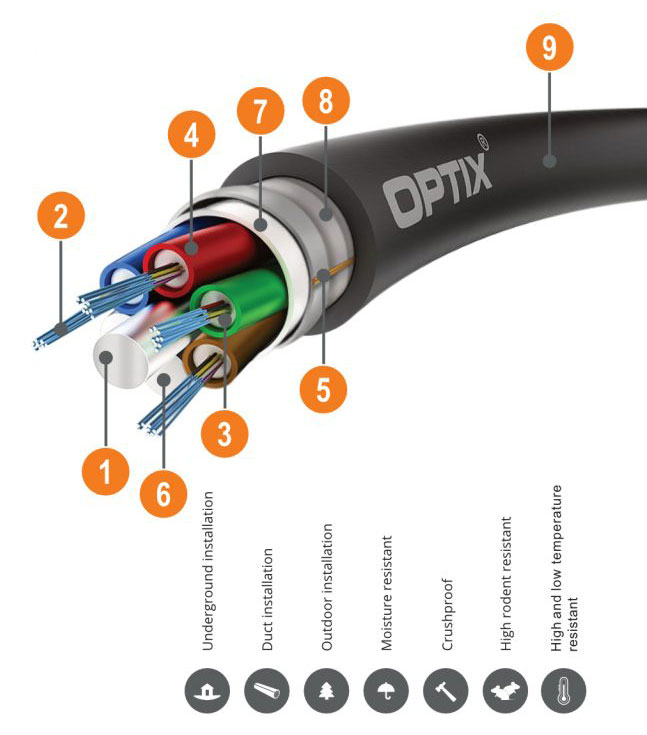

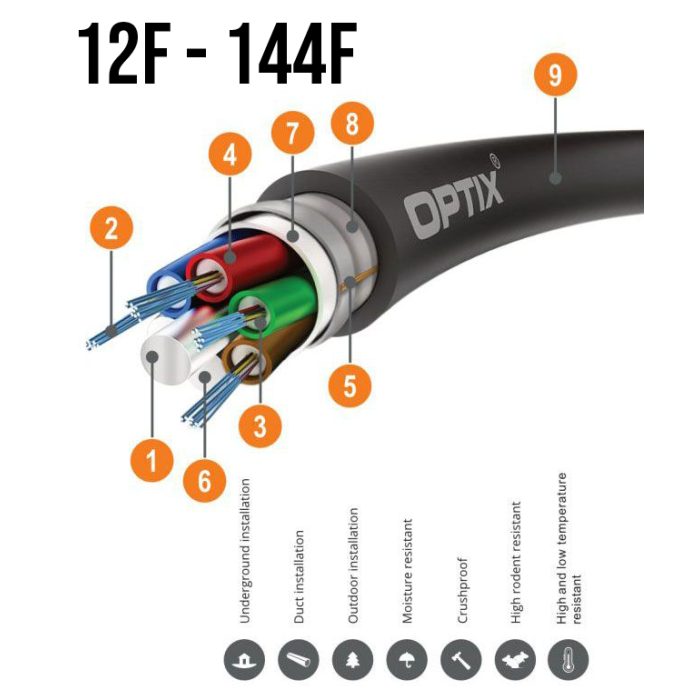

CABLE CONSTRUCTION

- FRP rod

- Optical fibres in 0.25mm coloured coating

- Hydrophobic jelly

- Loose tube

- Ripcords to tear the outer jacket

- Filler

- Water blocking tape / yarns

- Corrugated steel tape

- HDPE outer jacket (black)

OPTIX STRONG ZKS-XOTKtsFf cable (Steel tape): an outdoor opto-telecommunication cable meant for installation in sewage canalisation as well as direct burial into the ground, a solid multi-tube construction with a dry sealed core, great durability against dragging, a central strengthening element (FRP rod), loose tube, gel and a water blocking construction (WB), armoured by a corrugated steel strip, HDPE shell -UV radation resistant, temperature range between -30°C and +70°C - an equivalent to the ZKS-XOTKtsFf. Maximum installation tension: 2000N-3000N.

All fibres and tubes of the cable adhere to the "EIA/TIA-598" colour coding standard. Each tube containing up to 12 fibres is filed with a hydrophobic gel to protect against moisture and vibrations. The cable core is safeguarded against water penetration by moisture absorbing yarns (WSY) and/or an anti-humidity tape' The cables tubes and filler elements are twisted along a central strengthening element - the FRP rod. Two threads molten into the cable shell (ripcords) ease the removal of the cables outer layer. The cables are meant for installation in sewage canalisation by pneumatic (cable blowing) and mechanical (cable pulling) means, as well as for direct burial into the ground, their construction provides protection of the glass fibres rodents and mechanical damage.

|

| Product information | ||||||||||

| Cable version |

The total amount of fibres [pcs] |

Weight [kg/km] (±10%) |

∅ Cable [mm] (±0.5) |

∅ Tube [mm] (±0.15) |

Supporting element/ Peripheral reinforcement |

Reinforcing element [mm] (±0.1) |

Coating material & thickness [mm] (±0.2) |

Temp. range instalation |

Temp. range operating transport |

Minimum bending radius temporary permanent |

| 1T12F | 12 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 2T6F | 12 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 2T12F | 24 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 4T6F | 24 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 4T12F | 48 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 6T12F | 72 | 150 | 11.3 | 1.5/2.1 | Steel tape | FRP(2.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 8T12F | 96 | 185 | 12.5 | 1.5/2.1 | Steel tape | FRP inPE coat (2.5/3.5) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| 12T12F | 144 | 260 | 15.0 | 1.5/2.1 | Steel tape | FRP inPE coat (2.5/6.3) | HDPE(1.5) | -30° to +70°C | -20° to +70°C | 20D/10D |

| Mechanical parameters | EN standard | IEC standard | 12F | 24-96F | 144F | |

| Tensile Strength Installation | EN 187000 | IEC 60794-1-2-E1 | 2000N | 2500N | 3000N | |

| Tensile Strength Operation | EN 187000 | IEC 60794-1-2-E1 | 1000N | 1250N | 1500N | |

| Crushing resistance | EN 187000, m.504 | IEC 60794-1-2-E3 | 3000N (100x100mm) for 60 sec. | |||

| Repeated bending | EN 187000, m.507 | IEC 60794-1-2-E6 | 30 cycles [(20xD), 1kg] | |||

Please complete your information below to login.

Anmelden

Neuen Account erstellen