OPTIX DAC Z-XOTKtcd ITU-T G.652D 1.2kN

Ab 0,16 € 0,13 €

OPTIX Cable DAC (Direct Access Cable)Z-XOTKtcd 1.2kN 9/125 ITU-T G.652D/G.657A1/G.657A2

UNIVERSAL AERIAL/DUCT CABLES

- Designed for direct access the ground

- Fully dielectric construction

- Resistance to high and low temperatures

- Solid HDPE jacket (orange)

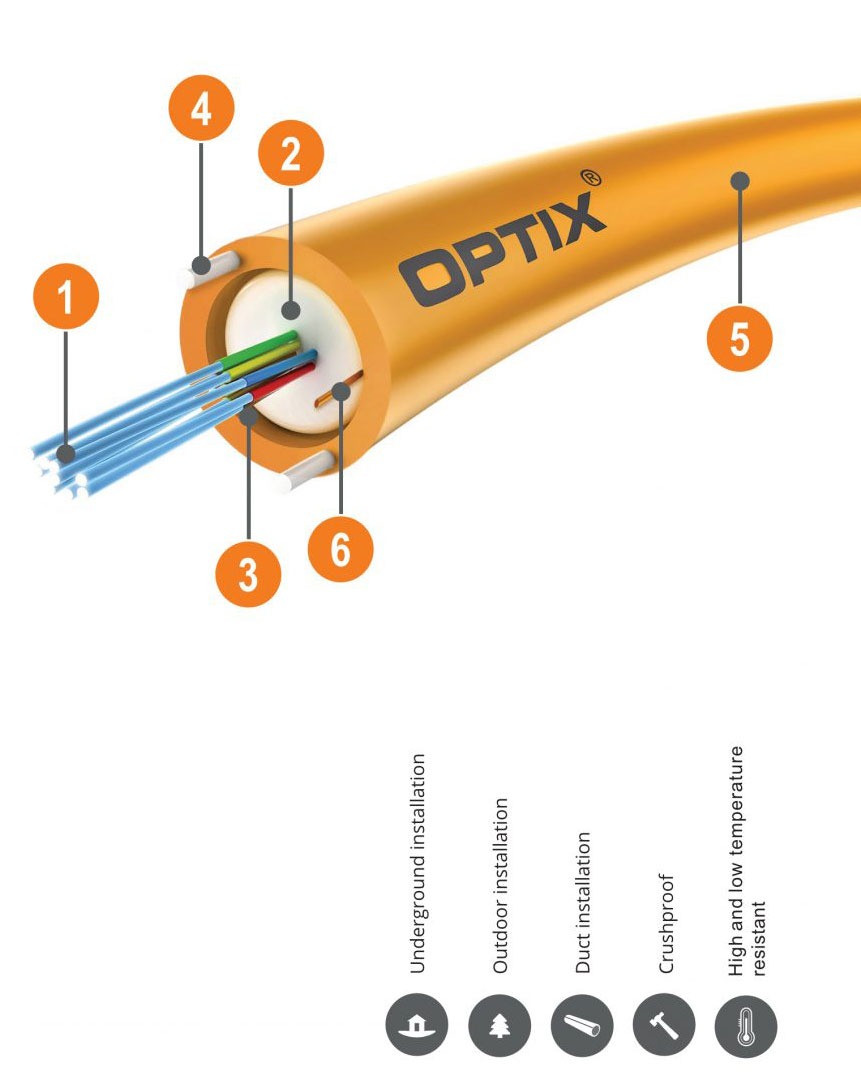

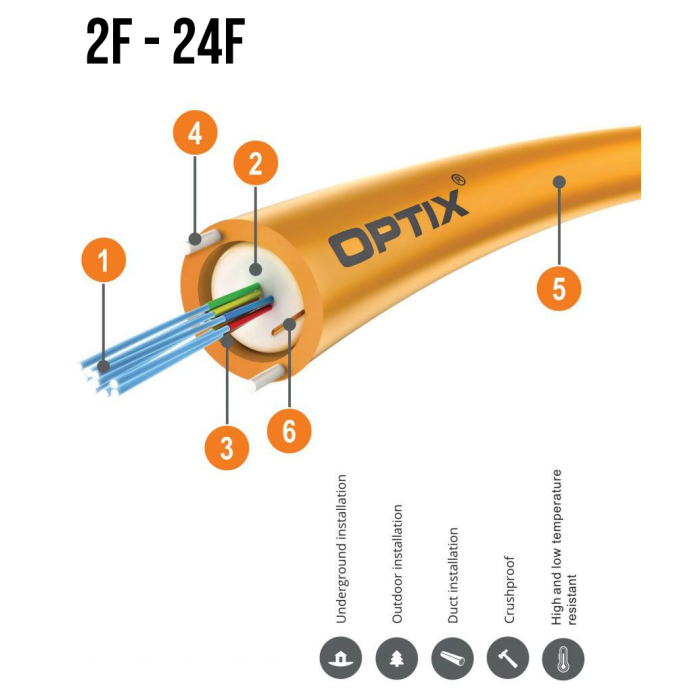

CABLE CONSTRUCTION

- Optical fibres in 0.25mm coloured coating

- Hydrophobic jelly

- Loose tube

- FRP rods

- HDPE outer jacket (orange)

- Ripcords to tear the outer jacket

OPTIX cable DAC Z-XOTKtcd: a lightweight single-tube construction of around 30kg/km, high flexibility and drag resistance, gel and water blocking structure (WB), HDPE coating (orange) temperature range between -20°C and +70°C, reinforced with 2 FRP rods (∅ 0.9mm), completely dielectric - equivalent to DAC Z-XOTKtcd. External cables designed for direct burial into the ground.

The cable design allows for easy installation and a high crush(1000N) and tensile(1200N) strength. All cable fibres have colour coding in accordance with the coding standard. The loose tube contains up to 24 optical fibres and is filled with a hydrophobic gel to protect the fibres from moisture and vibration. In order to provide additional structural strength - two FRP bars were embedded into the HDPE outer layer. Two threads also embedded in the jacket make it easier to remove the outer sheath of the cable (ripcords). Cables suitable for connecting last mile FTTH network clients.

|

| Product information | ||||||||||

| Cable version |

The total amount of fibres [pcs] |

Weight [kg/km] (±10%) |

∅ Cable [mm] (±0.5) |

∅ Tube [mm] (±0.15) |

Supporting element/ Peripheral reinforcement |

Reinforcing element [mm] (±0.2) |

Coating material & thickness [mm] (±0.1) |

Temp. range instalation |

Temp. range operating transport |

Minimum bending radius temporary permanent |

| 1T2F | 2 | 30 | 6.0 | 1.4/2.0) | None | FRP(2x0.9) | HDPE(1.8) | -20° to +70°C | -20° to +70°C | 20D/15D |

| 1T4F | 4 | 30 | 6.0 | 1.4/2.0) | None | FRP(2x0.9) | HDPE(1.8) | -20° to +70°C | -20° to +70°C | 20D/15D |

| 1T8F | 8 | 30 | 6.0 | 1.4/2.0) | None | FRP(2x0.9) | HDPE(1.8) | -20° to +70°C | -20° to +70°C | 20D/15D |

| 1T12F | 12 | 30 | 6.0 | 1.4/2.0) | None | FRP(2x0.9) | HDPE(1.8) | -20° to +70°C | -20° to +70°C | 20D/15D |

| 1T24F | 24 | 32 | 6.5 | 1.6/2.4) | None | FRP(2x0.9) | HDPE(1.8) | -20° to +70°C | -20° to +70°C | 20D/15D |

| Mechanical parameters | EN standard | IEC standard | 1-8F | 12F | 24F |

| Tensile Strength Installation | EN 187000 | IEC 60794-1-2-E1 | 1200N | 1200N | 1200N |

| Tensile Strength Operation | EN 187000 | IEC 60794-1-2-E1 | 600N | 600N | 600N |

| Crushing resistance | EN 187000, m.504 | IEC 60794-1-2-E3 | 1000N (100x100mm) for 60 sec. | ||

| Repeated bending | EN 187000, m.507 | IEC 60794-1-2-E6 | 30 cycles (20xD) | ||

Please complete your information below to login.

Anmelden

Neuen Account erstellen