OPTIX MICRO Z-XOTKtmd MC301 0.65-1.0kN

A partire da 0,58 € 0,47 €

OPTIX Cable MICRO Z-XOTKtmd MC301 0.65-1.0kN 9/125 ITU-T G.652D

MICRODUCT CABLE

- Cable for microduct installation

- Solid HDPE jacket

- Small reduced diameter

- Designed to cable blowing

- Water blocking construction

- Reinforced by FRP central Strengyh member

- Resistance to high and low temperatures

- Fully dielectric construction

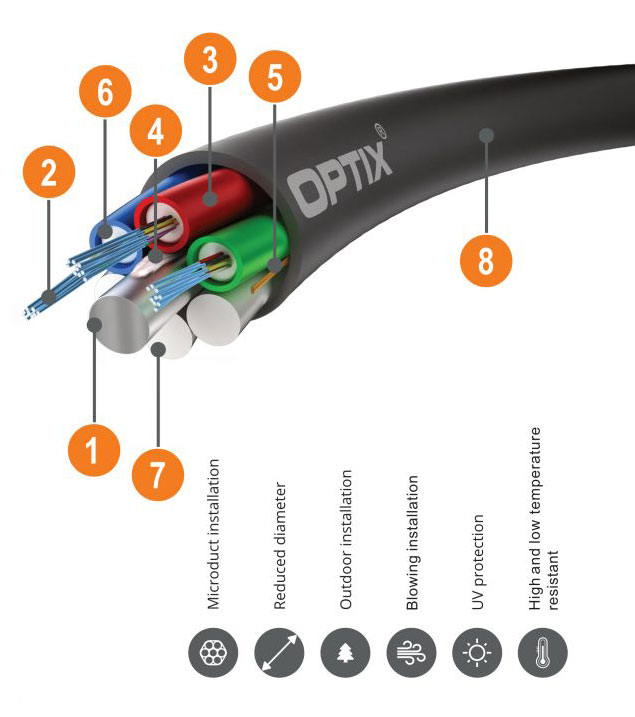

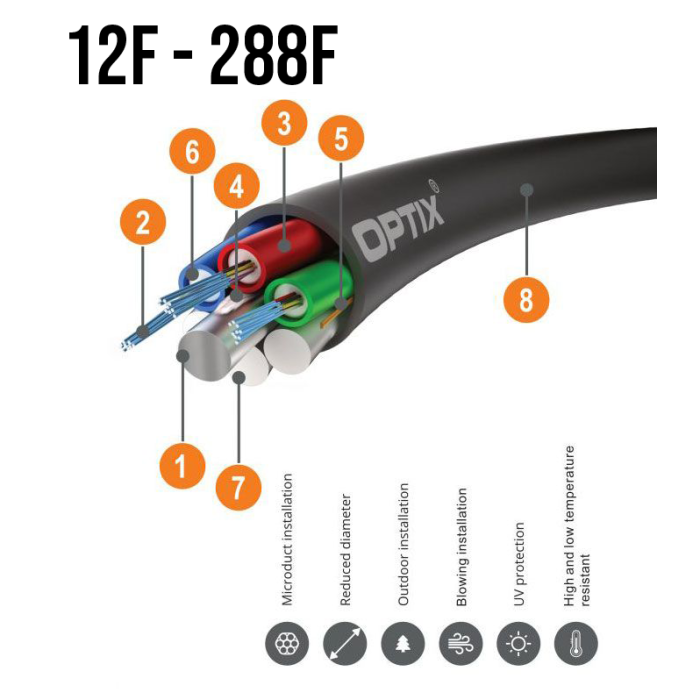

CABLE CONSTRUCTION

- FRP rod

- Optical fibres in 0.25mm coloured coating

- Loose tube

- Water blocking yarns

- Ripcords to tear the outer jacket

- Hydrophobic jelly

- Filler

- HDPE outer jacket (black), UV stabilized

OPTIX MICRO Z-XOTKtmd MC301 cable are a family of distributive micro-canalisation cables for micro-tubes of an internal diameter of up to 8mm (for 12 - 92 fibres), 10mm (for 144 fibres). A light small diameter construction, strengthened with a fibreglass rod, (0.5mm) HDPE coating, installation tension strength: 650-1000N, temperature range between -20°C and + 70°C - an equivalent to Micro Z-XOTKtmd.

All cable fibres and tubes adhere to the "EIA/TIA-598" colour coding standard. Each tube is filled with hydrophobic gel for anti-moisture and anti-vibration fibre protection. The cables are meant for installation in primary and secondary tele-technical canalisation by pneumatic (blow-in) methods.

|

| Product information | ||||||||||

| Cable version |

The total amount of fibres [pcs] |

Weight [kg/km] (±10%) |

∅ Cable [mm] (±0.3) |

∅ Tube [mm] (±0.1) |

Supporting element/ Peripheral reinforcement |

Reinforcing element [mm] (±0.1) |

Coating material & thickness [mm] (±0.1) |

Temp. range instalation |

Temp. range operating transport |

Minimum bending radius temporary permanent |

| 2T6F | 12 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 1T12F | 12 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 2T12F | 24 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 4T6F | 24 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 3T12F | 36 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 4T12F | 48 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 6T12F | 72 | 26 | 5.4 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 8T12F | 96 | 36 | 6.1 | 1.15/1.45) | None | FRP 2.4 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 12T12F | 144 | 52 | 7.9 | 1.15/1.45) | None | FRP in PE coat (2.4/4.1) | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 24T6F | 144 | 80 | 9.3 | 1.15/1.45) | None | FRP 2.80 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 16T12F | 192 | 52 | 7.9 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 18T12F | 216 | 52 | 7.9 | 1.15/1.45) | None | FRP 1.60 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| 24T12F | 288 | 80 | 9.3 | 1.15/1.45) | None | FRP 2.80 | HDPE(0.5) | -10° to +50°C | -30° to +70°C | 20D/10D |

| Mechanical parameters | EN standard | IEC standard | 12-72F | 96-144F | 192-216F | 288F |

| Tensile Strength Installation | EN 187000 | IEC 60794-1-2-E1 | 650N | 800N | 650N | 1000N |

| Tensile Strength Operation | EN 187000 | IEC 60794-1-2-E1 | 450N | 550N | 450N | 700N |

| Crushing resistance | EN 187000, m.504 | IEC 60794-1-2-E3 | 500N (100x100mm) for 60 sec. | |||

| Repeated bending | EN 187000, m.507 | IEC 60794-1-2-E6 | 25 cycles(20xD) | |||

Please complete your information below to login.

Accedi

Creare un nuovo account